PHONE 01934 834000 EMAIL SALES@STOWELLCONCRETE.CO.UK

Stowlite medium dense blocks/bricks 7.3N/mm² to BS EN 771-3

The Stowlite concrete block offers the builder an alternative product midway in the range between the dense concrete block and the high performance Fibotherm block. Stowlite blocks are widely used in a number of applications where high insulation is not such a priority. Being lighter than the standard dense block, handling is easier, often making savings on foundations and labour.

Standard Stowlite blocks provide a good finish for rendering. Stowlite blocks are available in close texture finish.

Slide title

Stowlite medium dense blocks 7.3N/mm²

Button

Slide title

Stowlite medium dense brick 7.3N/mm²

Button

| Size mm nominal (L x W x H) | approx weight kg | no. per tonne | multiples of | no. per pack |

|---|---|---|---|---|

| 440x100x215† | 14.5 | 68 | 44 | 88 |

| 440x140x215† | 19.5 | 51 | 32 | 64 |

| Size mm nominal (L x W x H) | approx weight kg | no. per tonne | no. per pack |

|---|---|---|---|

| 215x100x65 | 2.2 | 465 | 452 |

| 215x140x65 | 2.8 | 360 | 296 |

| SIZE mm | m²K/W at: | m²K/W at: |

|---|---|---|

| 100mm | 3% m/c 0.159 | 5% m/c 0.149 |

| 140mm | 3% m/c 0.222 | 5% m/c 0.209 |

TRANSVERSE TESTING: 100mm minimum 3.5kN

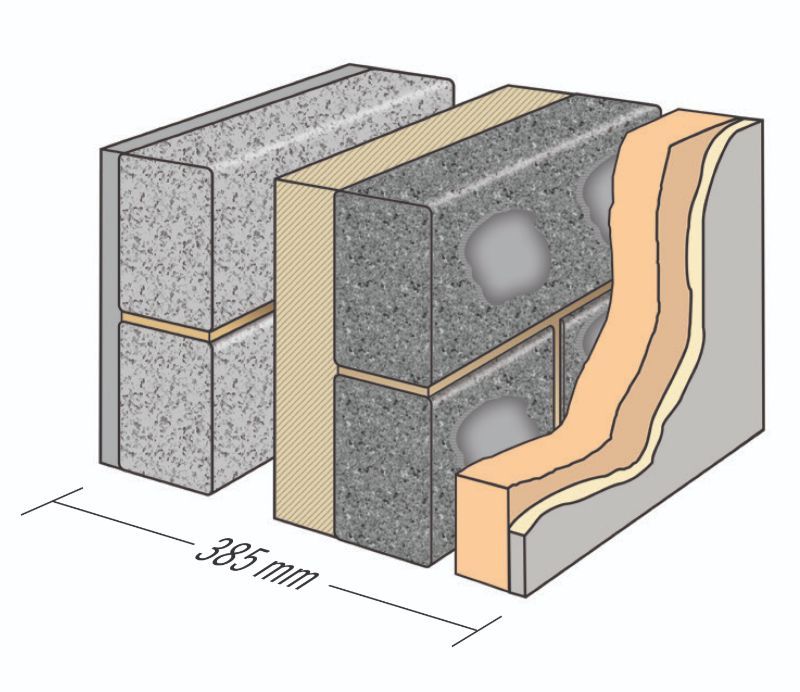

| Outside resistance | 0.040 |

| 19mm sand/cement render (λ1.00) | 0.019 |

| 100mm dense 7.3N/mm² (λ1.43) | 0.070 |

| 50mm low emissivity cavity | 0.640 |

| 50mm foil-faced partial fill PIR/PU board (λ0.022) | 2.273 |

| 100mm Stowlite 7.3N/mm² (λ0.63) | 0.159 |

| 15mm dabs | 0.170 |

| 37.5mm phenolic insulation (λ0.018) | 2.083 |

| bonded to… | |

| 13mm plasterboard (λ0.21) | 0.062 |

| Inside resistance | 0.130 |

| Sum of resistances | 5.646 m²K/W |

| Uncorrected U-value | 0.177 W/m²K |

| Mortar correction | 0.000 |

| Air gap correction | 0.002 |

| Wall tie correction – Staifix HRT4-225 | 0.002 |

| U-VALUE | 0.181 w/m²K |

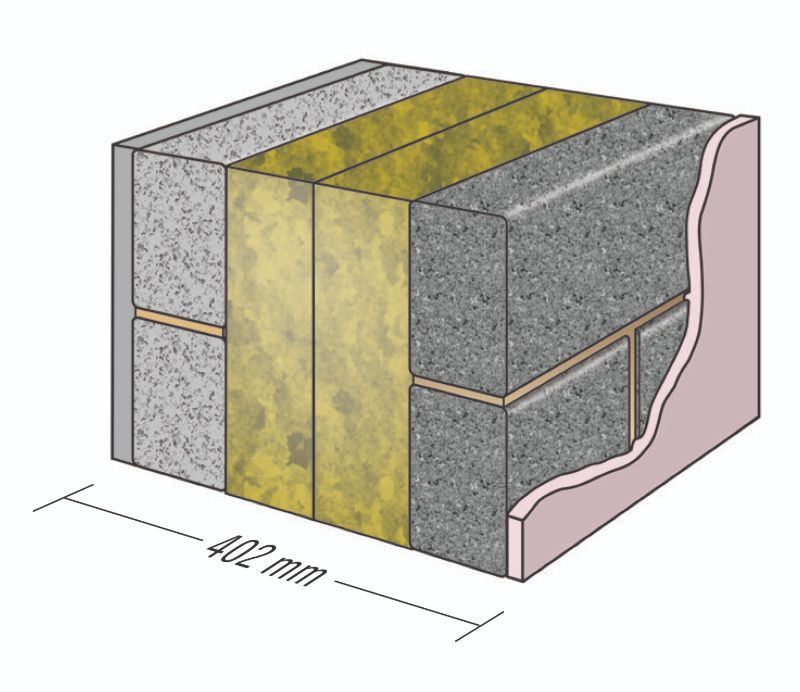

| Outside resistance | 0.040 |

| 19mm sand/cement render (λ1.00) | 0.019 |

| 100mm dense 7.3N/mm² (λ1.43) | 0.070 |

| 170mm high performance mineral wool (λ0.032) | 5.313 |

| 100mm dense 22.5N/mm² (λ1.52) | 0.159 |

| 13mm dense plaster (λ0.057) | 0.023 |

| Inside resitance | 0.130 |

| Sum of resistances | 5.754 m²K/W |

| Uncorrected U-value | 0.174 W/m²K |

| Mortar correction | 0.000 |

| Air gap correction | 0.000 |

| Wall tie correction – Ancon ST1-300 | 0.004 |

| U-VALUE | 0.178 W/m²K |

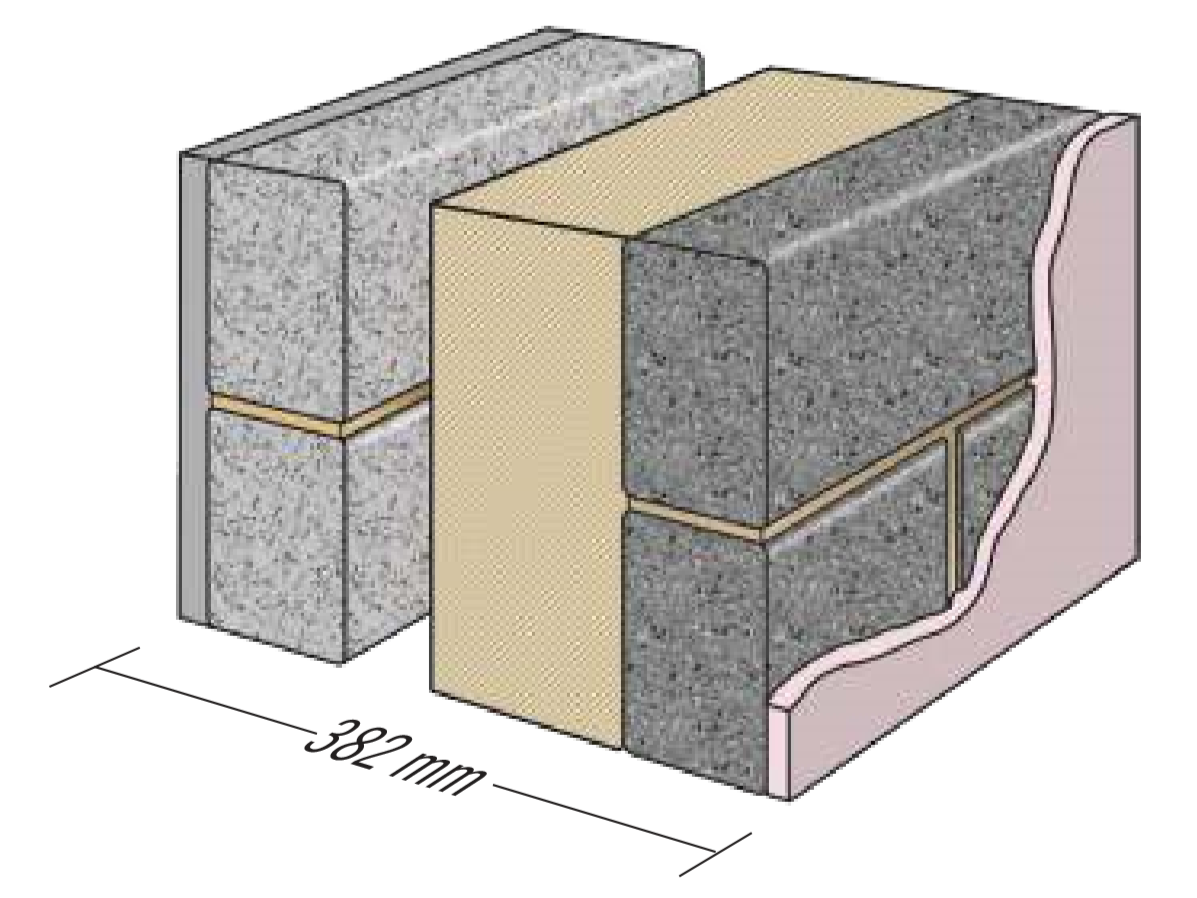

| Outside resistance | 0.040 |

| 19mm sand/cement render (λ1.00) | 0.019 |

| 100mm dense 7.3N/mm² (λ1.43) | 0.070 |

| 50mm low emissivity cavity | 0.640 |

| 100mm foil-faced partial fill PIR/PU board (λ0.018) | 5.556 |

| 100mm Stowlite 7.3N/mm² (λ0.63) | 0.159 |

| 13mm dense plaster (λ0.057) | 0.023 |

| Inside resistance | 0.130 |

| Sum of resistances | 6.637 m²K/W |

| Uncorrected U-value | 0.151 W/m²K |

| Mortar correction | 0.000 |

| Air gap correction | 0.007 |

| Wall tie correction – Staifix HRT4-225 | 0.005 |

| U-VALUE | 0.163 W/m²K |

PRIVACY POLICY | ENVIRONMENTAL POLICY | SUSTAINABILITY | RESPONSIBLE SOURCING | BIODIVERSITY | MODERN SLAVERY

PACKAGING | COSHH | BS EN ISO 14001 | BES 6001| SITEMAP | LOGIN

All Rights Reserved | Stowell Concrete Ltd