PHONE 01934 834000 EMAIL SALES@STOWELLCONCRETE.CO.UK

Stowlite medium dense blocks/bricks 10.4N/mm² to BS EN 771-3

Products

/ Stowlite medium dense blocks/bricks 10.4N/mm²

Stowlite 10.4N/mm2 blocks are approximately 22% lighter than the dense block of the same strength and provide a good background for rendering.

Slide title

Stowlite medium dense block 10.4N/mm²

Button

Slide title

Stowlite medium dense brick 10.4N/mm²

Button

Medium Dense Blocks ~ 10.4N/mm² (OVEN-DRY DENSITY approx 1600 kg/m³)

| Size mm nominal (L x W x H) | approx weight kg | no. per tonne | multiples of | no. per pack |

|---|---|---|---|---|

| 440x100x215† | 15.5 | 64 | 44 | 88 |

| 440x140x215† | 22.0• | 46 | 32 | 64 |

† Also manufactured in close texture. Click here

for photos and further information.

• Blocks in excess of 20kg – please use with caution after assessing the risks.

Coursing Bricks ~ 10.4N/mm² (OVEN-DRY DENSITY approx 1600 kg/m³)

| Size mm nominal (L x W x H) | approx weight kg | no. per tonne | no. per pack |

|---|---|---|---|

| 215x100x65 | 2.3 | 430 | 452 |

| 215x140x65 | 3.2 | 310 | 296 |

THERMAL CONDUCTIVITY: λ*

0.71 W/mK @ 3% m/c (Inside skin)

0.76 W/mK @ 5% m/c (Outside skin)

THERMAL RESISTANCE:

| SIZE mm | m²K/W at: | m²K/W at: |

|---|---|---|

| 100mm | 3% m/c 0.141 | 5% m/c 0.131 |

| 140mm | 3% m/c 0.197 | 5% m/c 0.184 |

(m/c = moisture content)

WEIGHTED SOUND INSULATION Rw:**

44 dB (100mm single skin, 209kg/m²)

46 dB (140mm single skin, 275kg/m²)

FIRE RESISTANCE:***

100mm 2 hrs

140mm 3 hrs

* Calculated from oven dry density

** Calculated using mass law curve - BS8233 (with 2 skins of dense plaster each 25kg/m²)

*** Calculated using table NA 3.2 BS EN 1996-1-2 : 2005 (unplastered separating load bearing single leaf walls)

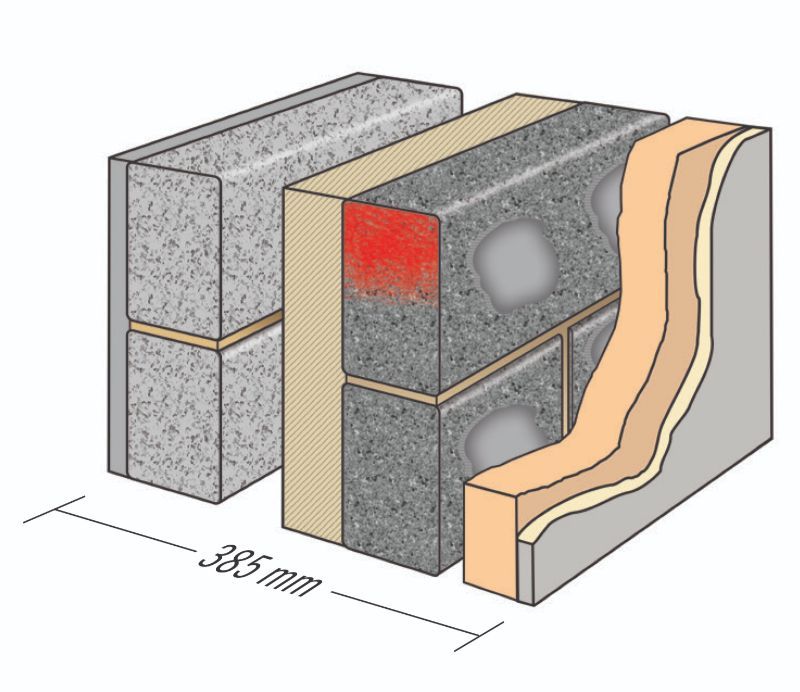

| Outside resistance | 0.040 |

| 19mm sand/cement render (λ1.00) | 0.019 |

| 100mm dense 7.3N/mm² (λ1.43) | 0.070 |

| 50mm low emissivity cavity | 0.640 |

| 50mm foil-faced partial fill PIR/PU board (λ0.022) | 2.273 |

| 100mm Stowlite 10.4N/mm² (λ0.71) | 0.141 |

| 15mm dabs | 0.170 |

| 37.5mm phenolic insulation (λ0.018) | 2.083 |

| bonded to… | |

| 13mm plasterboard (λ0.21) | 0.062 |

| Inside resistance | 0.130 |

| Sum of resistances | 5.628 m²K/W |

| Uncorrected U-value | 0.178 W/m²K |

| Mortar correction | 0.000 |

| Air gap correction | 0.002 |

| Wall tie correction – Staifix HRT4-225 | 0.002 |

| U-VALUE | 0.182 W/m²K |

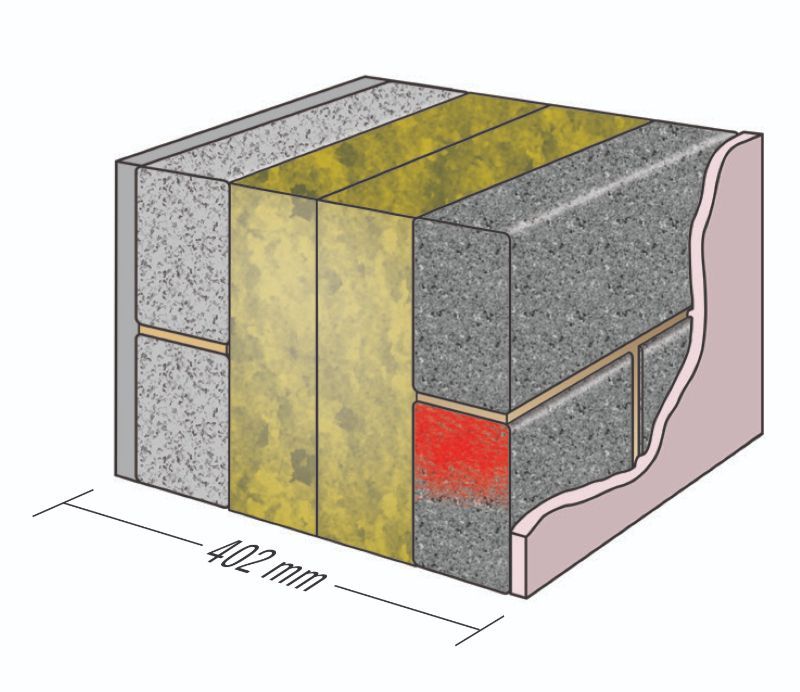

| Outside resistance | 0.040 |

| 19mm sand/cement render (λ1.00) | 0.019 |

| 100mm dense 7.3N/mm² (λ1.43) | 0.070 |

| 170mm high performance mineral wool (λ0.032) | 5.313 |

| 100mm Stowlite 10.4N/mm² (λ0.71) | 0.141 |

| 13mm dense plaster (λ0.057) | 0.023 |

| Inside resitance | 0.130 |

| Sum of resistances | 5.736 m²K/W |

| Uncorrected U-value | 0.174 W/m²K |

| Mortar correction | 0.000 |

| Air gap correction | 0.000 |

| Wall tie correction – Ancon ST1-300 | 0.004 |

| U-VALUE | 0.178 W/m²K |

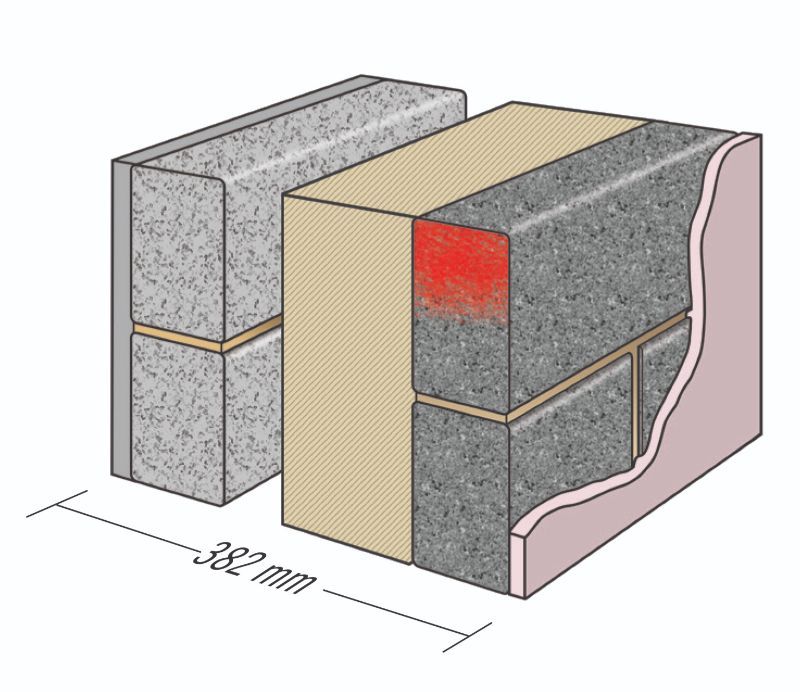

| Outside resistance | 0.040 |

| 19mm sand/cement render (λ1.00) | 0.019 |

| 100mm dense 7.3N/mm² (λ1.43) | 0.070 |

| 50mm low emissivity cavity | 0.640 |

| 100mm foil-faced partial fill PIR/PU board (λ0.018) | 5.556 |

| 100mm Stowlite 10.4N/mm² (λ0.71) | 0.141 |

| 13mm dense plaster (λ0.057) | 0.023 |

| Inside resistance | 0.130 |

| Sum of resistances | 6.619 m²K/W |

| Uncorrected U-value | 0.151 W/m²K |

| Mortar correction | 0.000 |

| Air gap correction | 0.007 |

| Wall tie correction – Staifix HRT4-225 | 0.005 |

| U-VALUE | 0.163 W/m²K |

PRIVACY POLICY | ENVIRONMENTAL POLICY | SUSTAINABILITY | RESPONSIBLE SOURCING | BIODIVERSITY | MODERN SLAVERY

PACKAGING | COSHH | BS EN ISO 14001 | BES 6001| SITEMAP | LOGIN

© 2025

All Rights Reserved | Stowell Concrete Ltd