PHONE 01934 834000 EMAIL SALES@STOWELLCONCRETE.CO.UK

Our Solar Journey

Embracing Solar Power: Stowell Concrete Ltd's Journey Towards Sustainable Production

At Stowell Concrete Ltd, our commitment to sustainability and innovation drives us to explore new ways to reduce our environmental impact while enhancing our production capabilities. Our journey towards greener operations began with the installation of solar panels on our Plant 6 production shed at Yatton. Covering an impressive 1.33 acres of space, these solar panels have significantly transformed our energy consumption practices.

Electric Forklifts Powered by Solar Energy

Following the success of our initial solar installation, we took another step forward by investing in electric forklifts that run on solar power. This move not only reduced our reliance on fossil fuels but also enhanced our operational efficiency. By using renewable energy to power our forklifts, we minimized our carbon footprint and demonstrated our commitment to sustainable practices in every aspect of our operations.

Solar Power: The Heart of our Static Block Plant

Our static block plant, responsible for manufacturing a wide range of products including KennStone Walling, concrete block paving, close textured blocks, bricks, and commons, now uses solar power as its primary energy source. This shift to renewable energy has allowed us to produce high-quality construction materials while significantly reducing our environmental impact. The solar-powered static block plant stands as a testament to our dedication to sustainable manufacturing practices.

Expanding Solar Power Across All Plants

Building on the success of our initial solar installations, we constructed a new production shed for block making at Yatton, covering an additional 1.67 acres with solar panels. This expansion further solidified our commitment to renewable energy and sustainable production practices.

In addition to our efforts at Yatton, we also installed solar panels on our T-beam production shed at Holcombe. This initiative extended our renewable energy coverage, contributing to a total of over 3 acres of shed space now covered in solar panels.

Our extensive use of solar power has greatly reduced our carbon emissions, contributing to a cleaner environment. By harnessing solar energy, we have decreased our dependency on fossil fuels and lowered our overall greenhouse gas emissions.

Check out our sustainability policy for more information on what Stowell Concrete are doing to reduce our gate-to-gate carbon emissions.

Innovation Inspired by Solar Power: The Solar Ballast Block

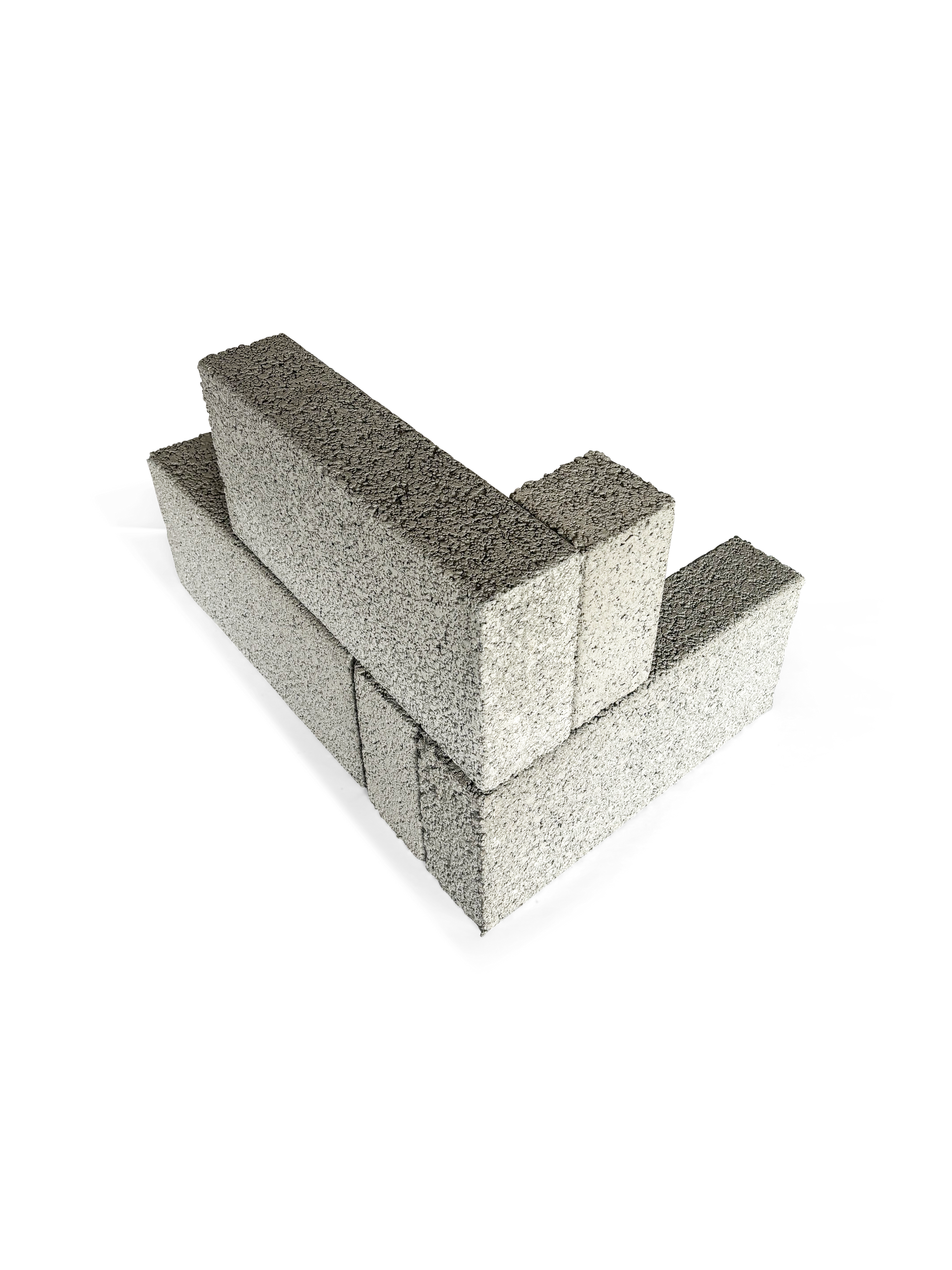

Our investment in solar panels inspired us to think more broadly about solar power, leading to the creation of our latest product: the Solar Ballast Block. Designed to support solar panel installations, the Solar Ballast Block is a testament to our commitment to innovation and sustainability.

Stowell Solar Ballast Blocks are designed to work with ground mounted table type framing systems so that piling is not required.

Solar Ballast Blocks are often the best solution for:

- Old landfill sites

- Flood plains

- Sites with archaeological interest

- Sites with utilities underground

- Sites which are cost saving

Stowell Solar Blocks are generally manufactured using a semi-dry 10.4N/mm² block mix using Class 1 limestone aggregates.

The proposed range will include two sizes, each with four heights. Stocks of each product will allow small jobs to be supplied ex stock, but bigger jobs are ideally manufactured about two weeks prior to delivery/ collection. Due to our manufacturing process, volumes of 750 full units or 1,500 half units can be produced per day.

PRIVACY POLICY | ENVIRONMENTAL POLICY | SUSTAINABILITY | RESPONSIBLE SOURCING | BIODIVERSITY | MODERN SLAVERY

PACKAGING | COSHH | BS EN ISO 14001 | BES 6001| SITEMAP | LOGIN

All Rights Reserved | Stowell Concrete Ltd