Kerbs, Edgings & Channels to BS EN 1340

We can produce kerbs, channels and fitments to suit most requirements of the road builder. Our hydraulically-pressed pre-cast concrete units are strong and durable and manufactured to strict tolerances. Standard kerbs have a pimpled finish and come in a standard shade of concrete grey.

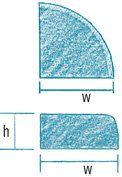

There are three basic profiles available:

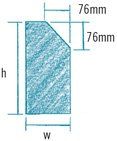

- BULL-NOSED

- HALF-BATTERED

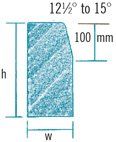

- FULL-BATTERED

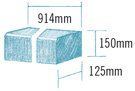

Our straight kerbs are 913mm in length with the most commonly used being the half-battered profiles which provide a check element sufficient to warn motorists that they are close to the edge of the carriageway. They are normally used where a footpath is provided adjacent to the carriageway. Full-battered profile kerbs are used where a vehicle may need to ride up onto a verge in an emergency, for safety reasons these are not used when a footpath is present. Where a crossing is required for access to a private driveway, access point or pedestrian crossing, the appropriate tapers and crossing kerbs are used.

KERBS

| Ref | Fig | W x H x L | Type | no. per tonne | no. per pack |

|---|---|---|---|---|---|

| BN1 | 2 | 150 x 305 x913 | Bull Nose Kerb | 10 | 14 |

| BN2 | 2 | 125 x 255 x 913 | Bull Nose Kerb | 14 | 16 |

| BN3 | 2A | 125 x 150 x 913 | Bull Nose Kerb | 23 | 16 |

| SP2 | 5 | 125 x 255 x 913 | Full Batter Kerb | 15 | 8 |

| SP3 | 5A | 125 x 150 x 913 | Full Batter Kerb | 24 | 8 |

| HB1 | 7 | 150 x 305 x 913 | Half Batter Kerb | 10 | 14 |

| HB2 | 7 | 125 x 255 x 913 | Half Batter Kerb | 15 | 16 |

| HB3 | 7A | 125 x 150 x 913 | Half Batter Kerb | 24 | 16 |

EDGINGS

| Ref | Fig | W x H x L | Type | no. per tonne | no. per pack |

|---|---|---|---|---|---|

| EF | 11 | 50 x 150 x 910 | Square Top | 63 | 40 |

| EBN | 13 | 50 x 150 x 910 | Single Bull Nose | 63 | 40 |

| EF | 11 | 50 x 200 x 910 | Square Top | 48 | 20 |

| EBN | 13 | 50 x 200 x 910 | Single Bull Nose | 48 | 20 |

| EF | 11 | 50 x 255 x 913 | Square Top | 36 | 20 |

| EBN | 13 | 50 x 255 x 913 | Single Bull Nose | 36 | 20 |

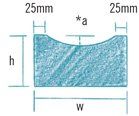

CHANNELS

| Ref | Fig | W x H x L | Type | no. per tonne | no. per pack |

|---|---|---|---|---|---|

| CS1 | 8 | 255 x 125 x 913 | Square Channel | 14 | 16 |

| CS2 | 8 | 150 x 125 x 913 | Square Channel | 23 | 16 |

| CD | 255 x 125 x 913 | Dished Channel | 15 | 16 | |

| CD | 150 x 125 x 913 | Dished Channel | 23 | 16 | |

| CD | 150 x 100 x 913 | Dished Channel | 30 | 20 | |

| 255 x 75 x 914 | Fluted Channel | 24 | 14 |

TRANSITIONAL KERBS

| Ref | Fig | W x H x L | Type | no. per tonne | no. per pack |

|---|---|---|---|---|---|

| DL1/DR1 | 16 | HB2-BN3 (fig.7-2A) | Tapers | 18 | 8 |

| DL2/DR2 | 16 | SP2-BN3 (fig.5-2A) | Tapers | 18 | 8 |

| BN2-BN3 (fig.2-2A) | Tapers | 18 | 8 | ||

| TL (fig.7 to 5) | Transitional Kerbs | 15 | 16 | ||

| TR (fig.5 to 7) | Transitional Kerbs | 15 | 16 | ||

| TL (fig.7 to 2) | Transitional Kerbs | 15 | 16 | ||

| TR (fig.2 to 7) | Transitional Kerbs | 15 | 16 | ||

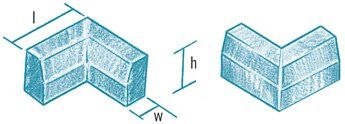

| Q HB/BN/SP | 14 | 305 x 255 | Quadrants | 24 | 15 |

| Q HB† | 14 | 455 x 255 | Quadrants | 10 | 8 |

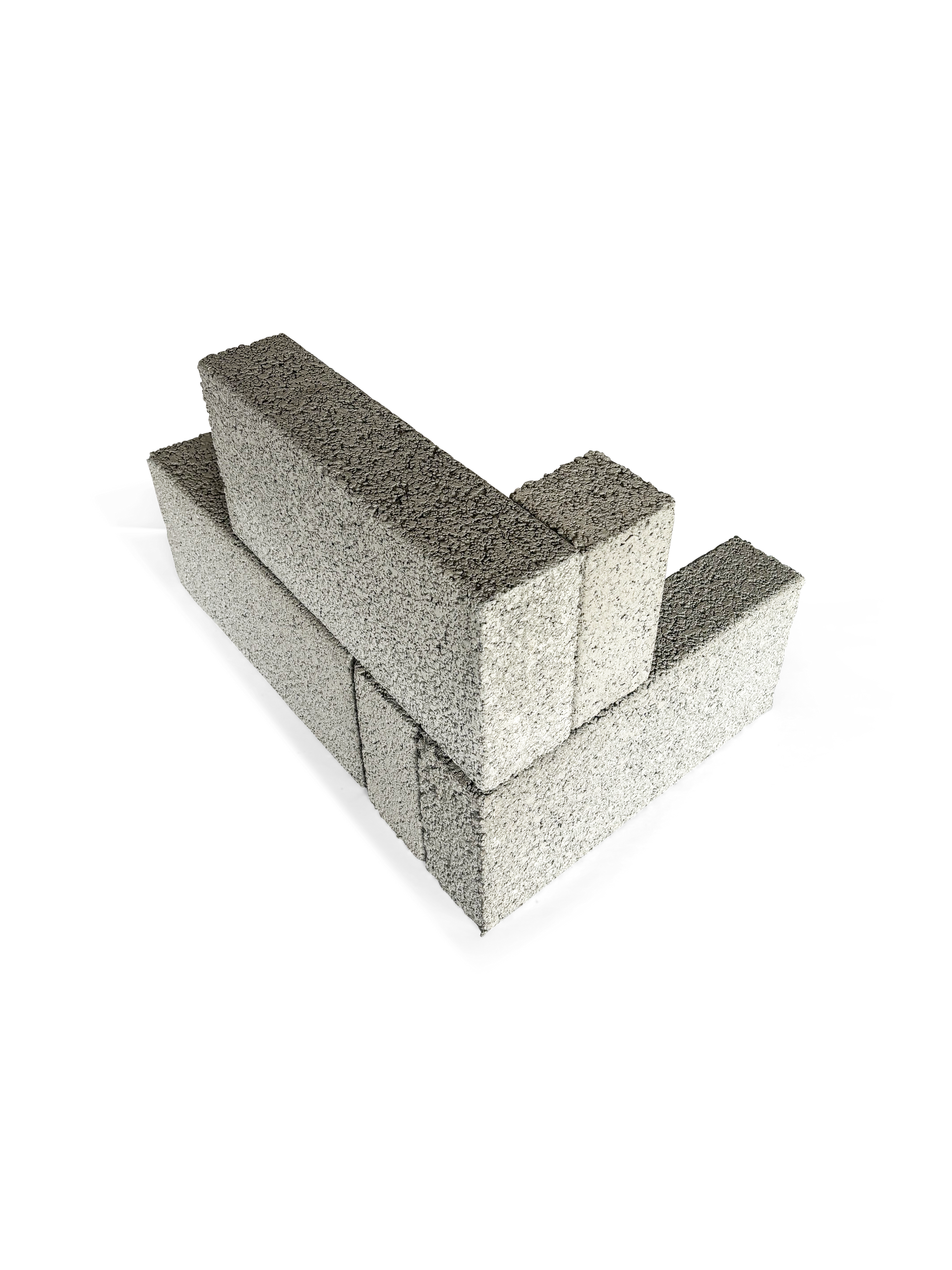

| IA HB/BN | 125 x 255 x 305 | Internal Angles | 27 | 16 | |

| XA HB/BN | 125 x 255 x 305 | External Angles | 27 | 16 |

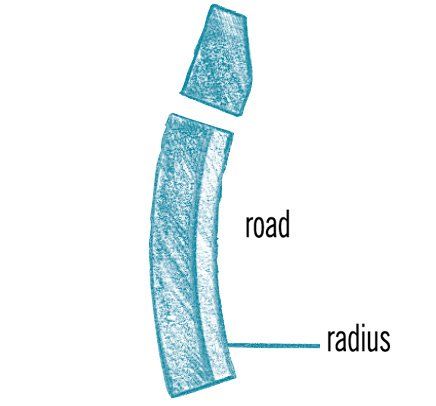

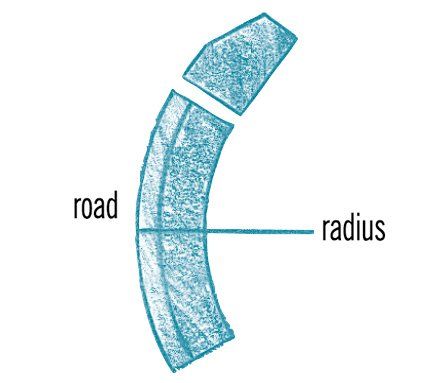

Radius Kerbs

| metres | feet | approx no. per circle |

|---|---|---|

| 1.0 | 3 | 8 |

| 2.0 | 6 | 16 |

| 3.0 | 10 | 22 |

| 4.0 | 13 | 28 |

| 4.5 | 15 | 32 |

| 6.0 | 20 | 44 |

| 7.5 | 25 | 54 |

| 8.0 | 26 | 56 |

| 9.0 | 30 | 64 |

| 10.5 | 35 | 76 |

| 12.0 | 40 | 86 |

| Ref | Fig | Size | 1 | 2 | 3 | 4 | 4.5 | 6 | 7.5 | 8 | 9 | 10.5 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BN2 | 2 | 125 x 255 | √ | √ | √ | √ | √ | ||||||

| BN3 | 2A | 125 x 150 | à | à | à | à | à | à | à | à | |||

| SP2 | 5 | 125 x 255 | √ | √ | √ | √ | √ | √ | √ | ||||

| HB2 | 7 | 125 x 255 | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||

| DLI/DRI | 16 | HB2-BN3 | √ | √ | √ | √ |

| Ref | Fig | Size | 3 | 4.5 | 6 | 7.5 | 9 | 10.5 | 12 |

|---|---|---|---|---|---|---|---|---|---|

| BN2 | 2 | 125 x 255 | |||||||

| BN3 | 2A | 125 x 150 | √ | √ | √ | √ | √ | √ | √ |

| SP2 | 5 | 125 x 255 | |||||||

| HB2 | 7 | 125 x 255 | √ | √ | √ | √ | √ | √ | √ |

| DLI/DRI | 16 | HB2-BN3 |

X-Tex Kerbs and Edgings to BS EN 1340

X-Tex Kerbs

The X-Tex textured kerb range builds on years of manufacturing experience, offering a more contemporary solution with an exposed surface finish.

Stowell Concrete have invested in secondary processing machinery to create the textured finish.

The textured kerbs are an upgrade to the traditional road kerbs, with the same strength and durability.

They are available in a bull-nosed profile, with a range of radii kerbs, tapers, quadrants, and angles to suit.

| Ref | Fig | W x H x L | Type | no. per tonne | no. per pack |

|---|---|---|---|---|---|

| BN2 | 2 | 125 x 255 x 913 | Bull Nose Kerb | 14 | 16 |

| BN3 | 2A | 125 x 150 x 913 | Bull Nose Kerb | 23 | 16 |

| BN2-BN3 | 16 | BN2-BN3 (fig. 2-2A) Right Hand | Tapers | 18 | 16 |

| BN2-BN3 | 16 | BN2-BN3 (fig. 2-2A) Left Hand | Tapers | 18 | 16 |

| EBN | 13 | 50 x 150 x 910 | Single Bull Nose Edging | 63 | 40 |

| EBN | 13 | 50 x 200 x 910 | Single Bull Nose Edging | 48 | 20 |

| EBN | 13 | 50 x 255 x 910 | Single Bull Nose Edging | 36 | 20 |

| QBN | 14 | 305 x 255 BN | Quadrants | 24 | 15 |

| IABN | 14 | 125 x 255 x 305 BN | Internal Angles | 27 | 16 |

| XABN | 14 | 125 x 255 x 305 BN | External Angles | 27 | 16 |

| Ref | Fig | Size | 3 | 4 | 4.5 | 6 | 7.5 | 8 | 9 | 10.5 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| BN2 | 2 | 125 x 255 | √ | √ | √ | √ | √ | ||||

| BN3 | 2A | 125 x 150 | √ | √ | √ | √ | √ | √ | √ |

| Ref | Fig | Size | 3 | 4.5 | 6 | 7.5 | 9 | 10.5 | 12 |

|---|---|---|---|---|---|---|---|---|---|

| BN3 | 2A | 125 x 150 | √ | √ | √ | √ | √ | √ | √ |

Clifton Kerbs & Edgings

A Premium Kerb Range

Clifton Kerbs are a premium kerb range, thoughtfully designed as an enhancement to the textured kerb and standard kerb ranges.

Building on years of manufacturing experience, the Clifton kerb range combines the robust durability of traditional concrete with the eye catching textured finish, enriched by black flecks of distinctive aggregates.

The exposed surface finish creates a striking effect designed to emulate the appearance of natural granite.

| Ref | W x H x L | Type | no. per tonne | no. per pack |

|---|---|---|---|---|

| CLIF02 | 125 x 255 x 915 | Clifton Kerb | 14 | 16 |

| CLIF04 | 125 x 150 x 915 | Clifton Kerb | 23 | 16 |

| CLIF03 | 255 x 205 915 | Clifton Kerb | 9 | 8 |

| CLIF09 | 125 x 255 - 125 x 150 | Tapers Left Hand | 18 | 16 |

| CLIF10 | 125 x 255 - 125 x 150 | Taper Right Hand | 18 | 16 |

| CLIF05 | 50 x 150 x 915 | Edging | 63 | 36 |

| CLIF01 | 63 x 150 x 915 | Edging | 63 | 30 |

| CLIF08 | 305 x 255 | Quadrants | 24 | 15 |

| CLIF07 | 125 x 255 x 305 | Internal Angles | 24 | 16 |

| CLIF06 | 125 x 255 x 305 | External Angles | 24 | 16 |

| CLIF11 | 125 x 255 x 915 | 3m Radius External | 14 | 16 |

| CLIF12 | 125 x 255 x 915 | 6m Radius External | 14 | 16 |

| CLIF13 | 125 x 255 x 915 | 10.5m Radius External | 14 | 16 |

| CLIF14 | 125 x 150 x 915 | 3m External Radius | 23 | 16 |

| CLI15 | 125 x 150 x 915 | 6m External Radius | 23 | 16 |

| CLIF16 | 125 x 150 x 915 | 10.5m External Radius | 23 | 16 |